Arc Machines Inc.

AMI Power Supplies

M217

Features

- WDR (Weld Data Recording): recording and saving weld data and exporting them to a storage device in their native or other file formats; saving project weld data records as a single file

- 12″ color touch-screen display

- Computer controlled internal memory for 1000+ weld schedules and up to 99 levels per schedule

- Manual or automated weld procedure generation Weld schedules: tack, pulsed, step, no-pulsed, tack, S3, and pulsed S3

M207

The 207 features a maximum memory capacity of 100 weld schedules with 100 levels per schedule and current pulse rate of .05-50 PPS.

Features

- Input Power Source: 100-240 VAC service, single phase 50/60 Hz

- Weld Current: 100-150A

- Dimensions: 11″x22.75″x18.75″

- Weight: 79 lbs

M217P

Features

- Light weight and portable

- Auto-switching of input voltages from 100 to 240, 50/60 hz

- Versatile, durable and ready to go anywhere

- 150 A maximum output possible on 100 vac/30 a input

M2Y7-CW

Features

- Interfaces to M217 power supply

- Independent / Stand-alone operation is possible

- Sensing for coolant flow

- Recommended use with De-ionized water w/Ethylene Glycol mixture

- Stackable design

- Built-in Circuit Breaker protection

- Service Cable & Ethernet extensions to allow the weld head to work further away from the Power Supply and Water cooler

AMI 8 Series

Product Description

The Model 8 series orbital weld heads are designed for fusion (TIG) welding of tube, thin-wall pipe and fittings through the range of 0.25 in. (6 mm) to 6.625in. (168 mm) OD (outside diameter) and wall thicknesses up to 0.160in. (4 mm). The narrow width of these heads makes them ideal for fitting-to-fitting welds and other limited-clearance applications.

The Model 8 series weld heads incorporate a two-sided clamping mechanism – precision machined and designed to compensate for significant diameter variances while ensuring positive clamping force and concentricity. The insert sizes accommodate an extensive range of applications and all Model 8 series weld heads are fitted with water-cooling capability – for heavy wall material welding and/or high duty-cycle requirements.

Features

- Fitting support mandrel – to facilitate the welding of short sanitary ferrules without pre-tacking

- Bench mount bracket – to provide secure support when not in use or when bench welding

- Clamp inserts – available in imperial and metric sizes, as well as non-standard sizes for custom applications

- Extension cables – available in 25 ft. (7.6 m), 50 ft. (15.2 m), and 75 ft. (22.8 m) lengths

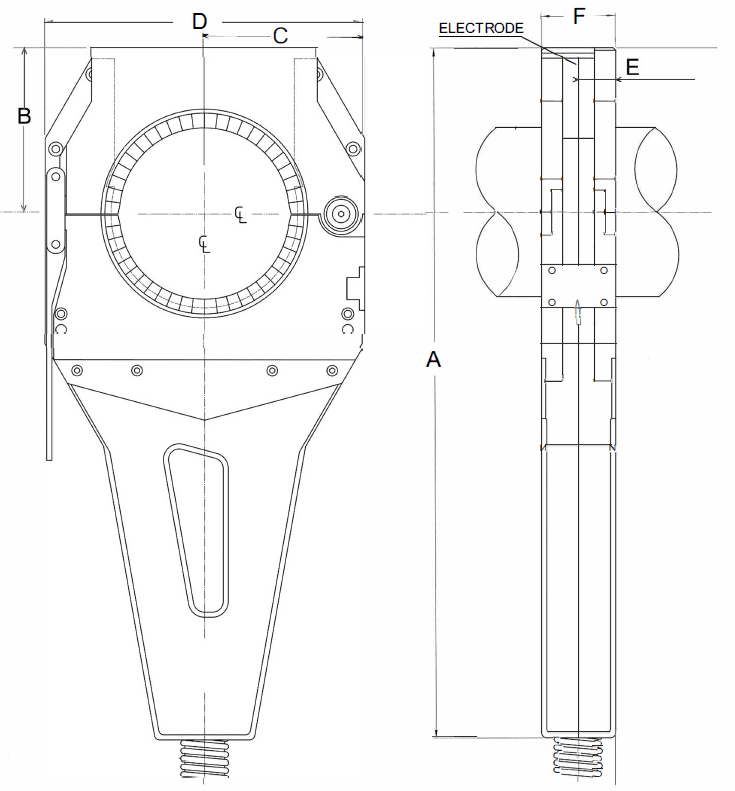

| Model Number | OD Range | Dimension A | Dimension B | Dimension C |

|---|---|---|---|---|

| M8-2000 | 0.25" - 2.00" | 13.44" | 2.81" | 2.75" |

| M8-4000 | 0.50" - 4.00" | 16.25" | 3.87" | 3.75" |

| M8-86625 | 2.00" - 6.625" | 20.26" | 5.42" | 5.50" |

Dimensional Drawing

AMI 9 Series

Product Description

Features

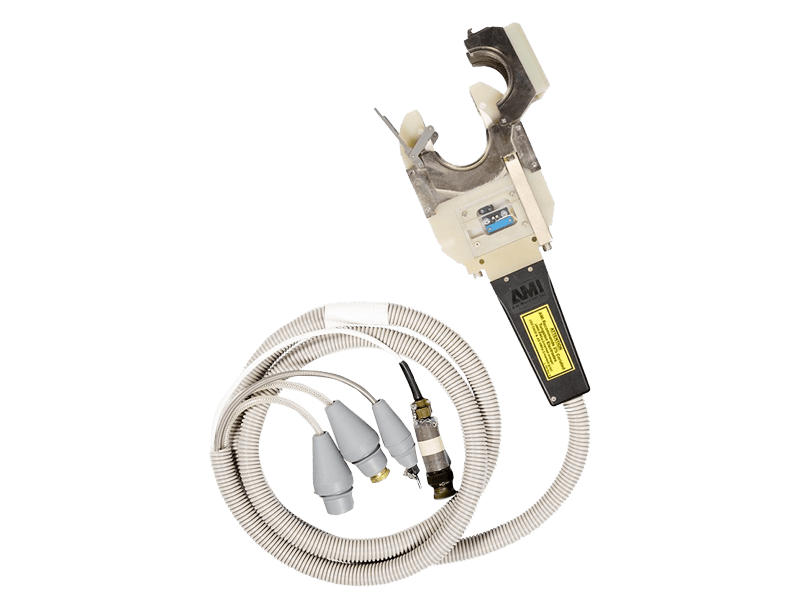

| Model Number | OD Range | Dimensions A | Dimensions B | Dimensions C | Dimensions D | Dimension E | Dimension F | |

|---|---|---|---|---|---|---|---|---|

| M9-250 | 0.093" - 0.250" | 10.00" | 0.83" | 0.66" | 1.31" | 0.25" | 0.48" | |

| M9-500 | 0.093" - 0.500" | 9.60" | 0.96" | 1.29" | 2.58" | 0.25" | 0.48" | |

| M9-750 | 0.125" - 0.750" | 11.30" | 1.19" | 1.38" | 2.75" | 0.70" | 1.40" | |

| M9-1500 | 0.250" - 1.500" | 13.00" | 1.88" | 2.00" | 4.00" | 1.41" | 2.81" | |

| M9-2500 | 0.750" - 2.500" | 15.75" | 2.62" | 2.88" | 5.75" | 1.72" | 3.44" | |

| M9-3500 | 1.000" - 3.500" | 16.75 | 3.12" | 3.63" | 7.25" | 1.72" | 3.44" | |

| M9-4500 | 1.500" - 4.500" | 19.00" | 4.25" | 4.50" | 9.00" | 2.00" | 4.00" | |

| M9-7500 | 2.875" - 7.500" | 22.00" | 5.68" | 6.12" | 12.25" | 2.16" | 4.32" |

Dimensional Drawing