AXXAIR Tube Facing

Tube facing is used on thin tubes with a thickness of less than 3 mm. It consists in bringing into conformity the end of a tube or an accessory. This conformity acts on three aspects:

The perpendicularity of the face of the tube -the surface state of the face – potentially a lengthadjustment.

After the facing process, the face will be perpendicular to the axis of the tube, without burrs, with a low RA and the desired length.

Facing machines are used when the cutting process is not sufficiently precise for the application or when the cutting processgenerates burrs.

To give an exemple: abrasive cutting disc, band saw or tube cutter. Tube with small diameters <25.4 mm are particularly concerned by the facing process. They are often cut with tube cutters or abrasive cutting machines. Generally speaking, tube must be faced before welding in order to obtain quality welds.

One category of tube is particularly concerned: electro-polished tube used in semiconductor or pharmaceutical industries.

It is forbidden to scratch the polished surface inside the tubes: the cuts are therefore only done with a cutting wheel. This process does not generate chips but only dust. The result of this cut is not exploitable without a facing operation which unrolls the chip towards the outside of the tube.

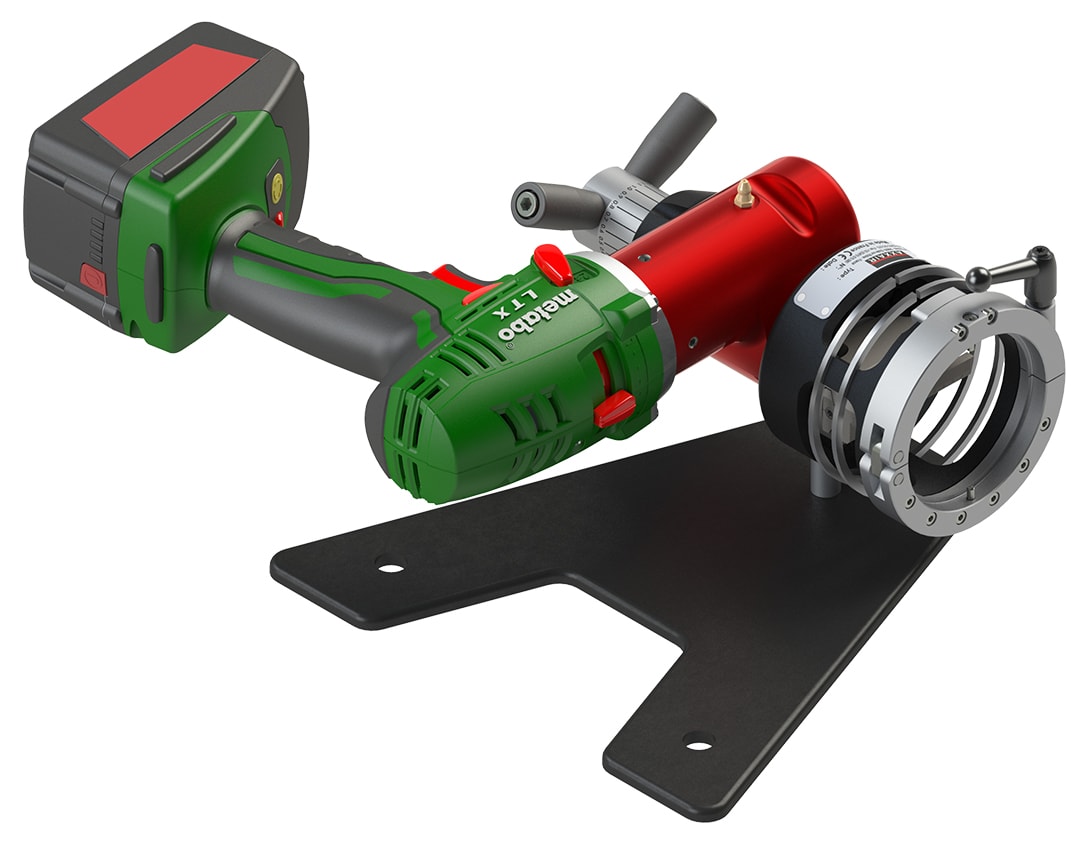

FLEXIBILITY, PRODUCTIVITY

Our facing machines operate on battery or corded for more flexibility TIALN blades, reversible with two cutting edges guarantee optimal lifetime of consumables.

QUALITY

Facing creates a clean and burfree surface without tube deformation: sharpness and accuracy guaranteed. Thin tube are therefore ready for welding.

PORTABILITY

Our facing machines are lightweight and designed to be used on site as well as in the workshop.

DC25

DC65

DC115-AM1

DC221-AMI