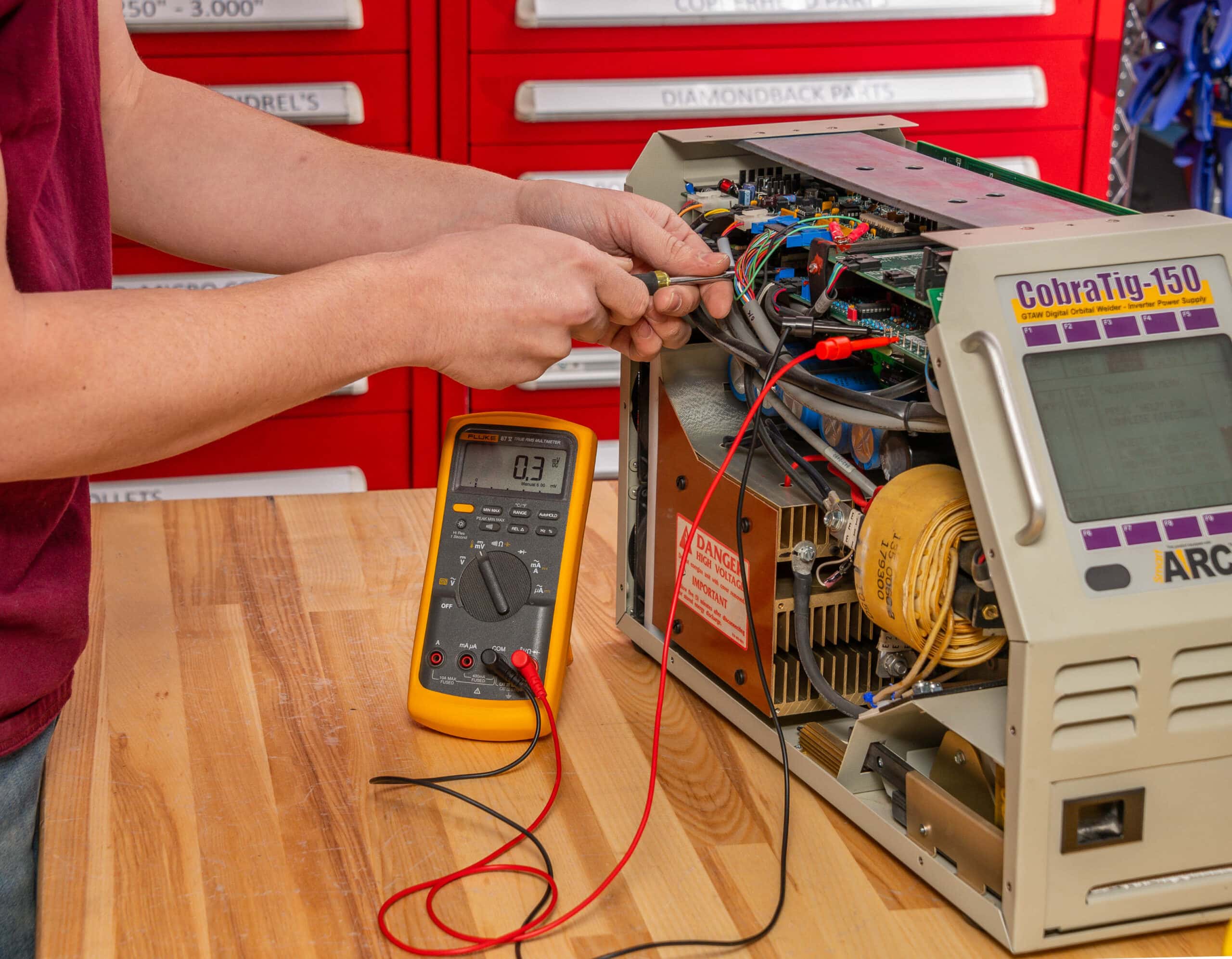

When you calibrate a machine, you’re verifying the degree to which it deviates from manufacturer or industry standards, ensuring that its performance falls within an acceptable range of tolerance. For orbital welding equipment, calibration is an inexpensive solution to confirm that voltage and amperage aren’t fluctuating outside of accepted standards where even small variations can compromise welds. This ensures repeatable current output and welds that are consistent and reliable for both quality and safety purposes.

At Precision Welding Supply, our qualified technicians have over 50 years of combined experience. Since 2004, our engineers, shop supervisors, job foremen, and quality assurance experts have served diverse industries with orbital welding services and supporting capabilities all under one roof. We’re equipped with advanced calibration machinery, which we certify annually per the National Institute of Standards and Technology (NIST) requirements. Read on to learn more about calibration and how we can support your operations.

Why Use Calibration Services?

You can think of equipment calibration as something comparable to yearly car inspections. The primary purpose of calibration services is to ensure that your equipment is performing as it should. In the case of orbital welding equipment, optimal performance means creating high-quality, repeatable welds.

Regular calibration of welding machines equates to taking a proactive approach in your equipment maintenance and repair. It’s highly beneficial for tending to older equipment. Even for newer machines, some jobs require that you recalibrate your welding equipment at least once per year, regardless of equipment age.

In addition to resetting equipment when you know there’s an issue, calibration services also allow you to uncover potential problems and premature part failure. You can address rust or other concerns before they can damage components like the weld head or negatively impact product quality. You’ll also prolong your equipment’s lifespan and reduce downtime in your operation, enabling you to meet your project deadlines.

Calibration Services You Can Rely On From Precision Welding Supply

At Precision Welding Supply, we understand that your products’ quality can only be as good as your equipment’s performance. Our expertise, machinery, welder calibration service offerings, and customer support are where we excel. We’ve calibrated hundreds of machines, giving us reliable proficiency in orbital welding and the ability to train you on welding equipment currently available in the market. Our expertise extends to multiple leading brands, including systems from:

- MK Products

- Liburdi Dimetrics

- AMI

- Magnatech

We’re also committed to responsiveness, promptly collaborating with you to successfully troubleshoot your equipment concerns.

Some misconceptions exist surrounding calibration, primarily having to do with cost and time. At Precision Welding Supply, we begin the process by gathering basic information on your equipment and scheduling an in-house calibration at our facility. Once we receive your orbital welding equipment, the typical turn time for calibrations is one to two days. We emphasize both speed and quality to give you peace of mind that your equipment is performing with precision accuracy while allowing you to get back to your projects faster.

Our team also provides value-added services including general inspections and equipment health checks. We’ll evaluate for rust, broken components, and parts that have reached the end of their service life and require replacements.

Partner With Precision Welding Supply

At Precision Welding Supply, we offer specialized, comprehensive orbital welding services, covering repairs, training, and rentals in addition to calibration at competitive prices. For your convenience, we also distribute orbital welding equipment from well-known brands. Our team of engineers, supervisors, and ASME Section IX-certified welders serves an international client base from our facility in the greater Philadelphia region, partnering with companies internationally in aerospace, energy, semiconductors, biotech, pharmaceuticals, food and beverage, and much more.

To schedule your orbital welding equipment calibration, contact us today.