MK Products

MK POWER SUPPLY

CobraTig® 150

Portable GTAW Orbital Tube Welder. A portable, lightweight orbital welding power source with a digital controller.

Features

- Provides automatic control of repeatability, verification and traceability.

- SmartArc® software develops a near-ideal weld procedure with Automatic Program Generator.

- Capable of going down to 0.1 Amps with MicroTig™ technology.

- High Voltage Pulse automatic arc starting from 0.5 to 25 Amps.

- SmartArc® control provides flexibility for orbital and manual welding.

Model Number and Line Power

| Model # | Line Power (± 10%) |

|---|---|

| 254-152 | 100VAC 50/60 Hz Single Phase, 15A |

| 120VAC | 50/60 Hz Single Phase, 15A |

| 208VAC | 50/60 Hz Single or Three Phase, 30A |

| 230VAC | 50/60 Hz Single or Three Phase, 30A |

Most Popular Accessories

- Thermal Printer Paper, 5 per package (Part Number 921-0170)

- MicroTig™ Manual Weld kit (Part Number 005-0670) includes gas-cooled hand TIG torch, variable foot control, ground cable with clamp and carry case.

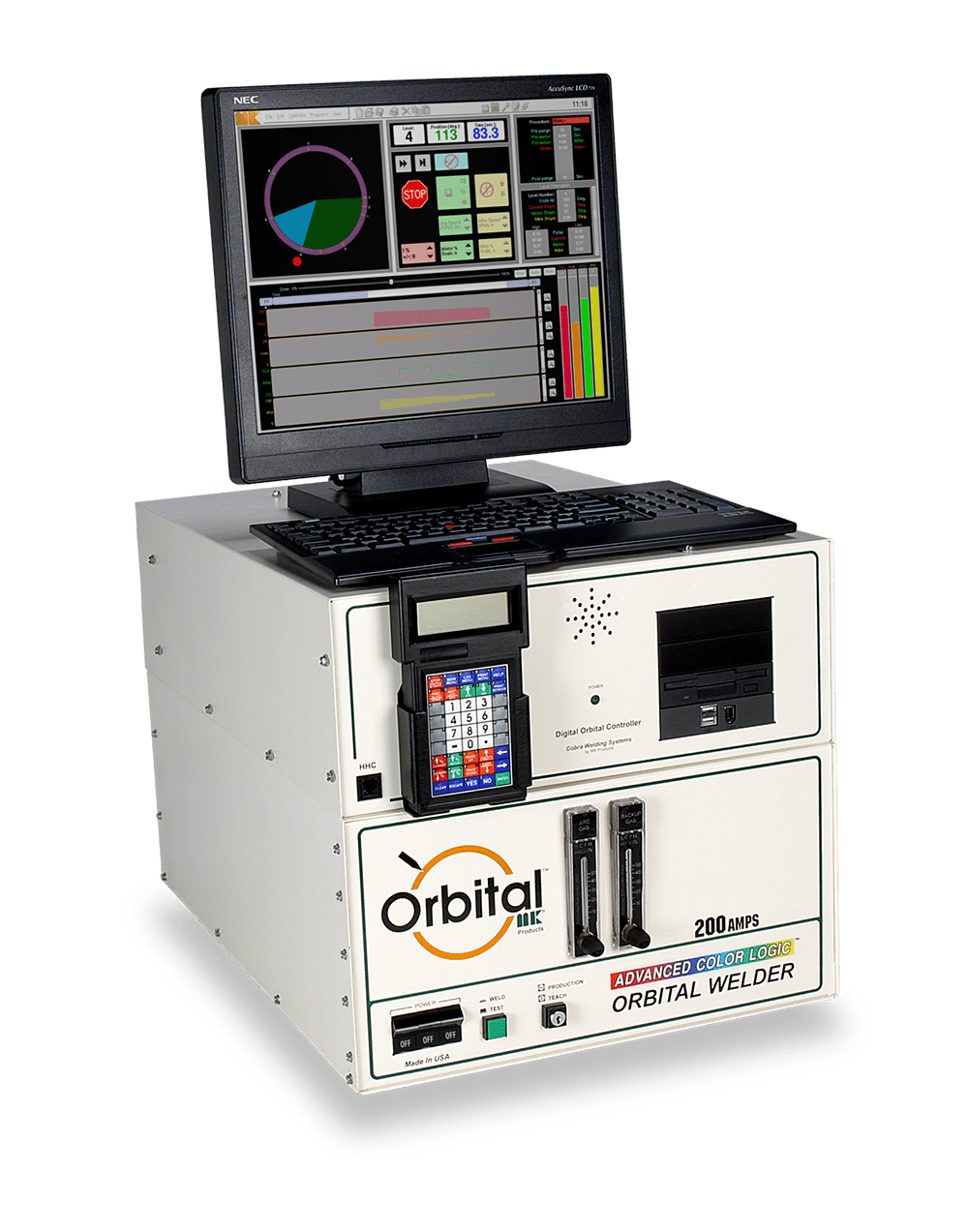

Advanced Color Logic®

Advanced Color Logic® – GTAW Orbital Power Supply / ControllerDelivers controlled welding current needed to perform high-integrity orbital tube welds.

The patented Advanced Color Logic® delivers controlled welding current needed to perform high-integrity orbital tube welds and is the perfect package for manufacturing environments.

Exclusive Auto Program Generator for easy weld setup and retrieval of saved procedures. Repeatability and precision, combined with real time data monitoring, traceability, and verification conform to most inspection and quality requirements. Pentium® class processor for the fastest real time on-screen visual display of all welding parameters. Playback entire weld graphically for analysis or download to offline computer.

Features

- Digital control and real-time graphics provide ease of operation and on-screen reference.

- Make your next weld while viewing the process in real time with 17” LCD flat screen monitor.

- Patented updated software now delivers more information, faster.

- USB equipped for moving, storing and transferring weld data and procedures.

- Programming is easy: just enter the tube diameter and wall thickness.

Model Number and Line Power

| Model # | Line Power (± 10%) |

|---|---|

| 254-202 | 120VAC 50/60 Hz Single Phase, 15A |

| 120VAC 50/60 Hz Single Phase, 15A, U | |

| 208/240VAC 50/60 Hz Single or Three Phase, 30A |

Most Popular Accessories

- ACL Protective Enclosure kit, (005-0375)

- Orbital Power Supply Calibration Kit (P/N 005-0698)

Additional Input Power Cords

- 120 VAC, Single Phase (P/N 843-0600)

- 208/240 VAC, Single Phase (P/N 843-0602)

- 208/240 VAC, Three Phase (P/N 843-0603)

- 220 VAC, Single Phase, Euro (P/N 843-0601)

- Universal 120 VAC, 30 A UL (P/N 843-0613)

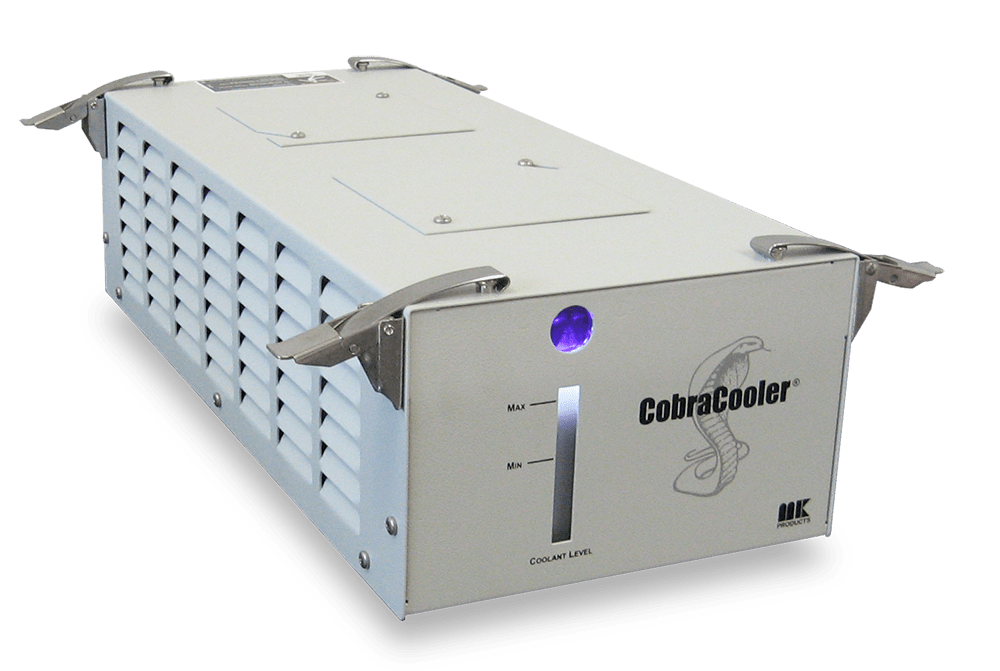

MK PRODUCT COOLER

CobraCooler

Portable Coolant Recirculator conveniently attaches mechanically to the CobraTig 150XM.

This recirculator is a separate stand-alone unit that conveniently attaches mechanically to an MK Products CobraTig® 150 welding power source.

The cooler provides recirculation of water to an attached weldhead that has provisions for Water Cooling.

The CobraCooler® is designed to be used with CopperHead® model orbital weldheads.

A CobraCooler®

Features

- Mechanically integrated assembly latches tightly under CobraTig 150 power supply.

- Provides water cooling for any MK Water Cooled weldhead.

- Includes high impact shipping case.

- Coolant Type: Use Cobra® Coolant (Aluminum Protection), P/N 931-0060.

- Cobra® Coolant required with the CobraCooler.

Model Number

Model Number 250-153

Cobra Coolant. Aluminum Protection. For improved performance with all orbital welding equipment like the CobraCooler and the CopperHeads, MK Products offers Cobra Coolant (931-0060).

- 1 Gallon (3.78L) P/N 931-0060

- 1 Case (4 Gallons) P/N 931-0060-4

Most Popular Accessories

- Weldhead extension cable, P/N 005-0635. It comes complete with all the necessary cabling to adapt the MK orbital weldheads: control cable with 24-pin connector, electrode and ground cables, inert gas hose and water hose assembly with quick-disconnect connectors. This 25-ft. extension cable is to mate any of the MK CopperHead series weldheads to the CobraCooler.

- A 50-ft is also available under P/N 005-0635-50.

Cobra® Coolant

Protect your MK Cobra welding system by keeping it cool. Cobra® Coolant – Aluminum Protection

Don’t forget to protect your MK Cobra Welding System by keeping it cool with Cobra® Coolant/Cobra Venom Juice.

Formulated especially for use in systems where aluminum parts are used. May also be used in any system where high frequency current is not present. Contains additives to inhibit algae growth and protection from freezing.

Improved Gun Performance For use with all Water Cooled MK Guns and Orbital

Features

- Designed for all Water Cooled Cobramatic Guns.

- For use with orbital welding equipment: the CobraCooler® and the CopperHeads®.

- Cobra® Coolant required with the CobraCooler®.

- Material Safety Data Sheet available.

Model Number and Line Power

Order by the bottle or by the case.

Part No. 931-0060: 1 Gallon (3.78 Liter)

Part No. 931-0060-4: 1 Case (4 Gallons)

A 1 gallon bottle of Cobra® Coolant

Safety – MSDS

- MSDS 091-0598 Rev A – Jun 2009Cobra Venom Juice/Coolant: View PDF

MK WELD HEADS

CopperHeads® Weldheads

GTAW CopperHeads® Weldheads

As our most cost effective and rugged in-place orbital weldhead, the CopperHead series is an ideal cost saver for sanitary and high pressure tube systems.All CopperHeads® are Water Cooled with fingertip controls in the weldhead handle and come ready to plug into the CobraTig® 150 SM and Advanced Color Logic® power sources. See Cobra® Coolant for more information.

Features

- Perfect for sanitary and high pressure tube & pipe jobs.

- Weld fitting collets, mandrels & special tooling available.

- CopperHead offers versatility and high-output production rates.

- CopperHeads® are Water Cooled, narrow profile ideal for awkward welds with limited access.

Model Number and Line Power

| Model # | Diameter Range | Cooling requirements |

|---|---|---|

| 5001 | I 1/8” ~ 1” O.D. | Yes |

| 5002 | II 1/4”~ 2” O.D. | Yes |

| 5003 | III 1/2” ~ 3” O.D. | Yes |

Most Popular Accessories

- CopperHeads® I-III Benchmount Kit

- Extension Cables Available: 25 ft (7.6m) – (P/N 005-0635)

50 ft (15.2m) – (P/N 005-0635-50)

DiamondBack Weld Heads

GTAW DiamondBack™ Weldheads

The DiamondBack™ is our largest in-place orbital weldhead. Heavy duty and versatile, the DiamondBack™ has a narrow profile and is perfect for process piping and weld fitting applications found in food & beverage, dairy and other sanitary process piping installations.

Features

- Perfect for sanitary and high pressure tube & pipe jobs.

- Weld fitting collets, mandrels & special tooling available.

- DiamondBack™ great for high-pressure aerospace applications.

Model Number and Line Power

| Model # | Diameter Range | Cooling requirements |

|---|---|---|

| 5006 | 2″ O.D. ~ 6″ O.D. | No |

Most Popular Accessories

- DiamondBack™ Benchmount Kit (P/N 005-0680)

- Extension Cables Available: 25 ft (7.6m) – (P/N 005-0635)50 ft (15.2m) – (P/N 005-0635-50)