Contract Orbital Welding Services

Orbital welding is a preferred welding method due to its efficiency and accuracy. Learn more about contract orbital welding, Precision Welding Supply’s services, and common applications of the process.

What Is Orbital Welding?

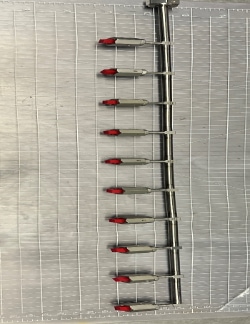

Another caption about this…

Our Contract Orbital Welding Services

The team at Precision Welding Supply has over five decades of combined experience in orbital welding. As specialists in orbital welding, we offer various contract orbital welding services, including repairs, rentals, and training to a diverse customer base. Our offices are in the greater Philadelphia region.

Customers rely on our orbital welding services for several key reasons, including:

- Fast job completion: Unlike manual welding, orbital welding uses specialized and automated welding equipment, making work easier and faster.

- Quality: An orbital weld made with the correct welding tool and settings will result in a high-quality weld.

- Cost-effectiveness: Another reason why customers need orbital welding is its cost-effectiveness. Since it is quick and highly automated, it cuts down on labor costs and production times. When customers work with us, each project has its own rate based on scope, so customers pay only for what they need.

- Subject matter experts: Precision Welding Supply specializes in orbital welding only, meaning we are very familiar with most orbital welding brands and the methods necessary to deliver the high-quality results our customers expect.

- Open communication: We maintain open communication channels with our customers throughout their projects so that they receive the results they require on time.

Our contract orbital welding services can help your company with the following pain points:

- No in-house orbital welding: If your company doesn’t have in-house orbital welding capabilities, you can benefit from using our contract orbital welding services. You don’t have to invest in acquiring and maintaining in-house orbital welding machines.

- Broken orbital welding equipment: Breakdown in orbital welding equipment may halt operations at your company. Precision Welding Supply offers rental equipment while our technicians service your orbital equipment.

- Overflow: When you have a large volume of welding work that exceeds your company’s capabilities, outsourcing the extra work to Precision Welding Supply can help increase production capacity to meet your deadlines.

- Quick job turnaround: We can help your company handle projects that need quick turnaround times. We have specialized equipment and the expertise to complete any contract orbital welding job faster than most in-house teams.

- Lack of certifications: Manual welding requires businesses to find manual welders with the necessary certifications. Orbital welding only needs a trained technician who can operate the equipment. Precision Welding Supply has experienced instructors who can train your in-house technicians to operate orbital welding equipment.

Applications of Orbital Welding

Orbital welding is a highly pure, contaminant-free, and efficient contract welding solution used in various industries.

Aerospace

The automated orbital welding process ensures standardization and uniformity in aerospace manufacturing. The high-quality and reliable welds produced are ideal for this industry’s strict standards of repeatability and tight tolerances.

Food and Beverage

Many pipes and tubes used in food production and packaging processes are products of orbital welding. Orbital welding is ideal for making reliable tube joints that work smoothly without leakage while meeting the sanitation and cleanliness standards of this industry.

Pharmaceutical

Pharmaceutical processes rely on pure, contaminant-free pipes and tubes. Orbital welding provides high-quality welds that protect the integrity of sensitive pharmaceutical compounds.

Oil and Gas

In the oil and gas industry, orbital welding guarantees leak-free pipes and tubing to carry corrosive substances.

Semiconductor

The semiconductor industry has some of the highest standards for preserving product integrity. Orbital welding is an ideal service that can create high-quality welds that meet these standards.

Contract Orbital Welding Services From Precision Welding Supply

When looking for an orbital welding service partner, you must consider their expertise, quality, turnaround time, and more. At Precision Welding Supply, our experienced team specializes in orbital welding so that we can offer the highest-quality welding services, training, repairs, products, and rentals. We offer just-in-time (JIT) shipping, quick turnaround times, and are certified per ASME Section XI Boiler and Pressure Vessel Code.

Contact us to learn more about our contract orbital welding services.